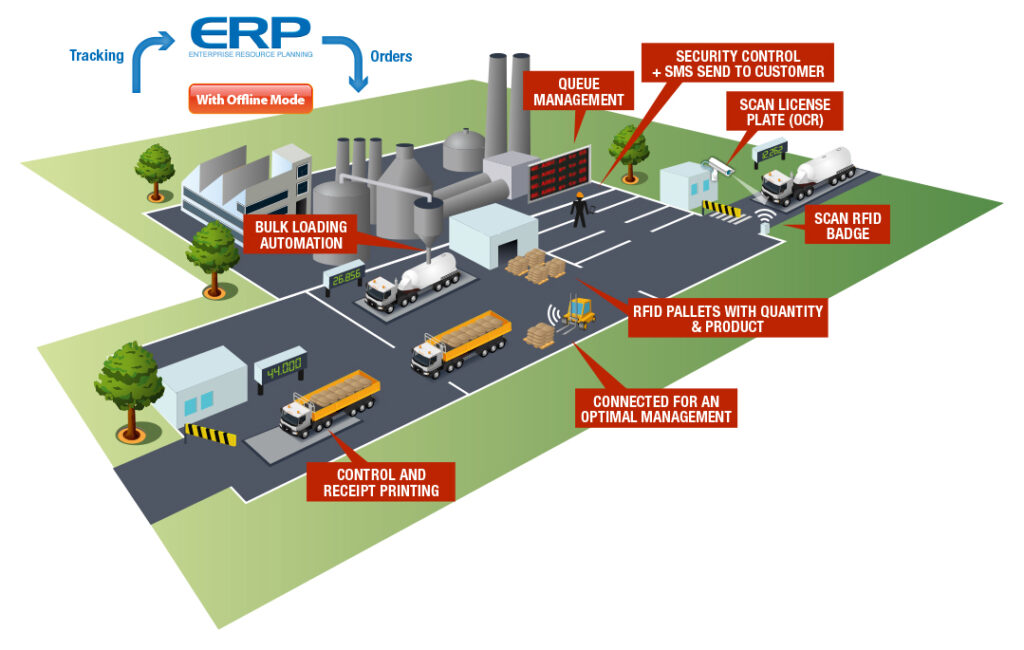

A solution for controlled trucking flows

IBITruck is a software solution based largely on Microsoft technologies, allowing the automation of the loading and unloading of vehicles on an industrial site.

The product is based on a centralized management system that manages all the events and transactions of the site.

Users of the system can access all functionalities wherever they are on site via desktop computers, touch-screen terminals, industrial stations, PDAs.

The solution is designed to integrate with your processes and is based on the following technologies:

IBITruck is a complete solution with a global approach to logistics issues.

The vehicle will be taken in charge as soon as it arrives at the entrance of the site, as well as at each point of passage and loading/unloading, until the exit of the site.

It is a very flexible solution that can be perfectly interfaced with existing tools and installations on an industrial site.

IBITruck is constantly evolving and has matured thanks to the combination of our skills in automation and industrial computing over the years.

It has undergone thousands of days of development to arrive at a solution that provides maximum customer satisfaction through :

Thanks to its reporting system, it allows to obtain a precise follow-up of the flows:

In general, all data stored in the database can be retrieved and presented to the various departments.

The application can handle :

SITE ACCESSES

MANAGEMENT

WEIGHING

MANAGEMENT

ERP TRANSACTION

MANAGEMENT

VEHICLES TRACEABILITY ON SITE

BY RFID/QR AND VIDEO

LOADING – UNLOADING VEHICLES

AUTOMATION PROCESS

MONITORING AND ANALYSIS

REPORT GENERATION

Operation of the vehicle identification on the industrial site

TIERCE

TAGS

READERS

Overview of the devices available on IBITruck

RFID/QR

- Tags (vehicle, pallet, product).

- Badges (Driver, Employee).

- RFID badge dispenser/advancer.

AUTOMATED SYSTEMS

- Goods loading/unloading

- Weighbridge

- Barrier

- Lights

CAMERAS

- OCR license plate

- Picture taking (of loading, weighing, documents)

- Surveillance camera

IHM APPLICATIVE

- RFID / Wifi handheld terminals

- RFID / Wifi on-board terminals for forklifts

- Industrial stations

- Multimedia terminals (screen, intercom, printers)

- Workstation on the administrative network